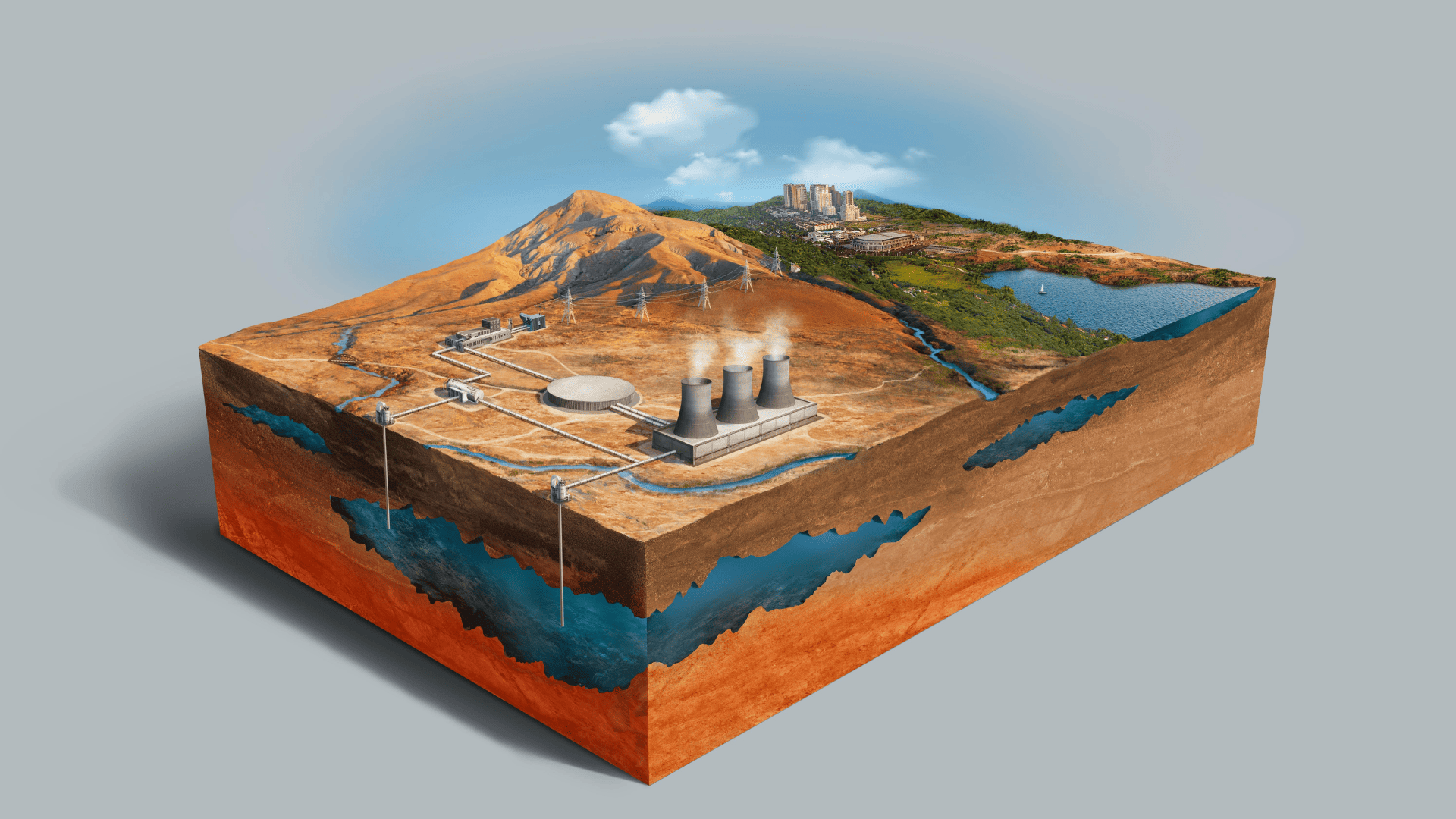

Geothermal energy is enjoying remarkable growth in the current context of energy transition. This technology, which draws energy from groundwater to power heat pump systems, represents a promising solution for heating and cooling buildings. However, harnessing this natural resource brings with it major technical challenges, not least protecting heat exchangers from the fine particles present in groundwater. It is in this context that specialized filtration solutions, such as Hectron’s AS range of low-pressure filters, become essential to guarantee the performance and longevity of geothermal installations.

A booming geothermal market

The groundwater geothermal market is enjoying sustained growth, driven by environmental policies and economic incentives in favor of renewable energies. Geothermal installations on aquifers are multiplying, whether for collective buildings, industrial facilities or urban development projects. This technology has the advantage of providing stable, continuous energy, regardless of weather conditions, with a particularly attractive coefficient of performance.

The challenges of geothermal filtration

Water drawn from groundwater is never perfectly pure. It naturally contains suspended particles: fine sands, clays, organic matter, metal oxides and other elements liable to settle on heat exchange surfaces. These particles, often very small in size, can pass through conventional filtration systems and accumulate in heat pump plate heat exchangers.

The resulting fouling phenomenon leads to a gradual reduction in the system’s thermal efficiency. Deposits reduce the effective heat exchange surface and increase pressure losses, forcing pumps to work harder to maintain nominal flow rates. Eventually, this degradation can lead to a complete shutdown of the plant, necessitating costly cleaning or exchanger replacement operations.

The problem is made all the more complex by the fact that geothermal systems often operate at relatively low pressures. Water boreholes rarely reach pressures in excess of 2 bar, which limits the choice of applicable filtration technologies. Traditional filtration systems, designed for high-pressure networks, are not suited to these particular conditions.

The importance of low-pressure filtration

Faced with these specific constraints, automatic low-pressure filters represent the most appropriate technical solution. Mainly used to protect plate heat exchangers, Hectron AS filters have the advantage of being able to operate at very low pressure: 0.5 bar of upstream pressure is sufficient. This fundamental characteristic enables them to be integrated into all types of geothermal installations, even those with restrictive hydraulic conditions.

The filtration range offered extends from 6 to 500 microns, offering great flexibility of adaptation according to water quality and the level of protection required. Most commonly, 80 to 200 micron filtration is sufficient to protect the plates. For certain boreholes containing large quantities of fine clays, much finer filtration (6 microns) can slow down the formation of deposits on the plates.

This graduated approach enables protection to be optimized according to the specific characteristics of each site, while maintaining the flow rates required for the geothermal plant to operate correctly.

Hectron AS filters: an innovative technical solution

Hectron’s AS range of automatic filters is distinguished by a design specifically adapted to the constraints of geothermal energy. Available in three main models, they cover a wide range of flow rates to meet the varied needs of the market: the AS 200 low-pressure automatic filter can handle a maximum flow rate of 45 m3/h, while the AS 300 model can handle a maximum flow rate of 120 m3/h, and the AS 400 can handle up to 340 m3/h.

The automatic cleaning system is the major asset of these units. Triggered by pressure differential measurement, it guarantees continuous operation without human intervention. This automation considerably reduces operating costs and minimizes the risk of production stoppages due to filter clogging. The backwashing process is carried out without shutting down the plant, and consumes only a small amount of water, thus conserving resources.

The absence of consumables is another significant economic advantage. Unlike cartridge or bag filter systems, which require regular replacement, AS filters work only with permanent filter elements, reducing operating costs over the long term.

Concrete benefits for geothermal systems

Installing Hectron AS filters on geothermal circuits generates measurable and lasting benefits. Effective protection of heat exchangers helps maintain nominal plant performance over many years of operation. Coefficients of performance (COP) remain stable, guaranteeing the expected energy efficiency of the geothermal system.

Another significant economic advantage is the reduction in maintenance operations. Exchanger cleaning operations, which are costly and technical, become much less frequent. This reduction in production stoppages improves plant availability and contributes to optimizing the return on investment of the geothermal project.

Improving the overall reliability of the plant is also a crucial asset. By eliminating the risk of sudden clogging of exchangers, automatic filters contribute to the operational stability of the system. This enhanced reliability is particularly appreciated in the context of multi-family buildings or industrial installations, where continuity of service is paramount.

Experience feedback and successful applications

The effectiveness of Hectron’s geothermal solutions has been confirmed by numerous reference installations. Major energy companies such as Veolia, Engie, Suez and Axima regularly use these technologies for their geothermal projects. This feedback demonstrates the ability of AS filters to meet the technical and economic requirements of professional installations.

Applications cover a wide spectrum, from small collective buildings to large-scale industrial installations. This versatility is due to the modularity of the range and the ability to fine-tune filtration parameters to the characteristics of each site.

Future prospects

The evolution of the geothermal market towards increasingly efficient and sustainable installations reinforces the importance of adapted filtration systems. Increasingly stringent environmental regulations are encouraging project owners to opt for tried-and-tested technical solutions, guaranteeing the longevity of their investments.

Ongoing innovation in the field of automatic filtration, supported by specialist manufacturers such as Hectron, is helping to anticipate the future needs of the geothermal sector. Constantly improving performance, reducing operating costs and optimizing integration into existing installations are priority areas for development.